Lifting And Deep Waves Price List Ball Mill Liners

.jpg)

The Selection and Design of Mill Liners 911 Metallurgist

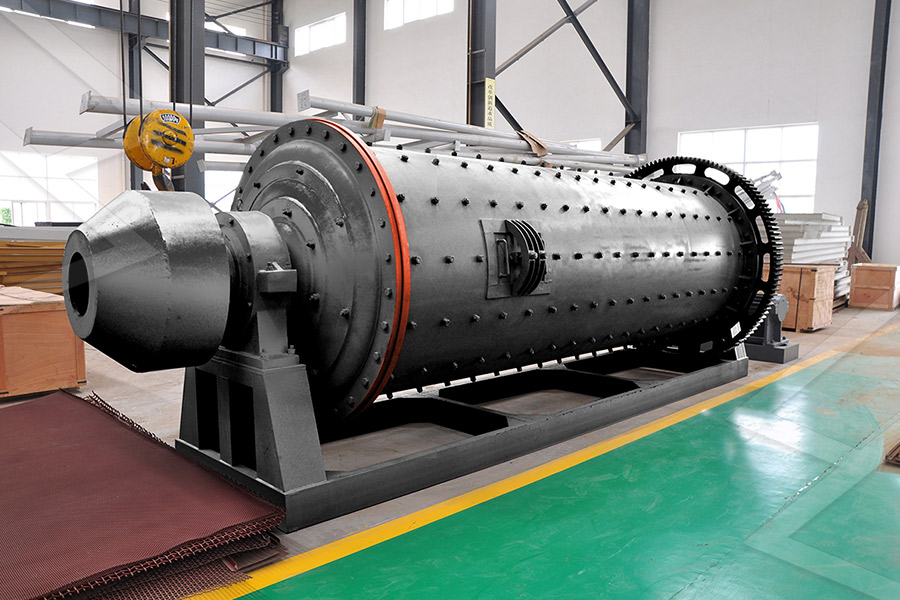

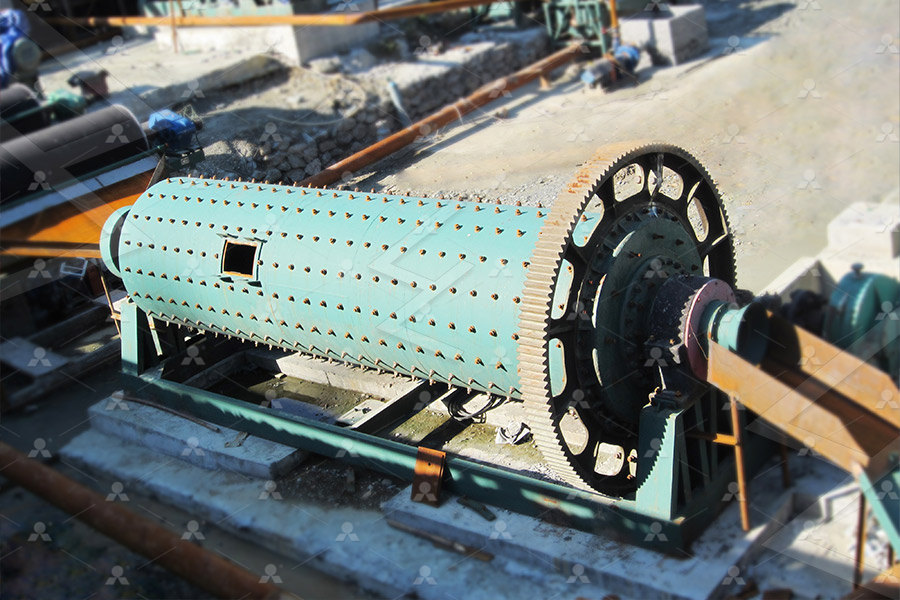

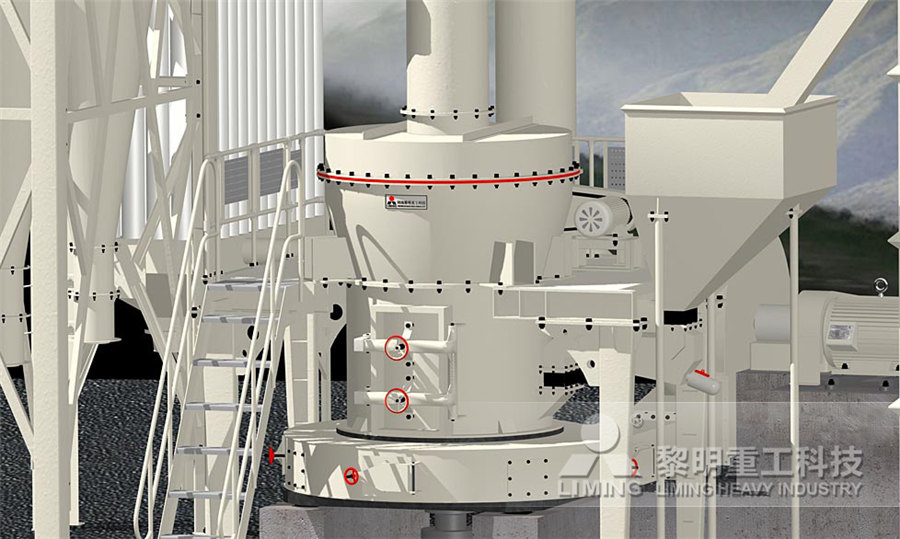

2024年9月24日 High–low double wave ball mill liners – These are a refinement of the wave liner, Figure 5 This was applied to Cadia Hill Gold Mine through evaluation of their existing wear Lifting And Deep Waves Ball Mill Liners 5 4 Types of wear behaviour for wave liners and RME Liner Handling Russell Mineral Equipment MILLMAST MAX Liner Handler is an efficient Lifting And Deep Waves Price List Ball Mill Liners2020年9月6日 Polycorp Ball Mill Liners provide long, low maintenance, service life In addition to protecting and sealing the ball mill’s steel shell, the liner imparts motion into the ball charge Ball Mill Liners for Mineral Beneficiation Polycorp2024年1月9日 and efficient lifting in ball mills, even as wear progresses, remains a persistent challenge That’s why we’re introducing our innovative family of lifting liners that merges Introducing an innovative family of lifting liners

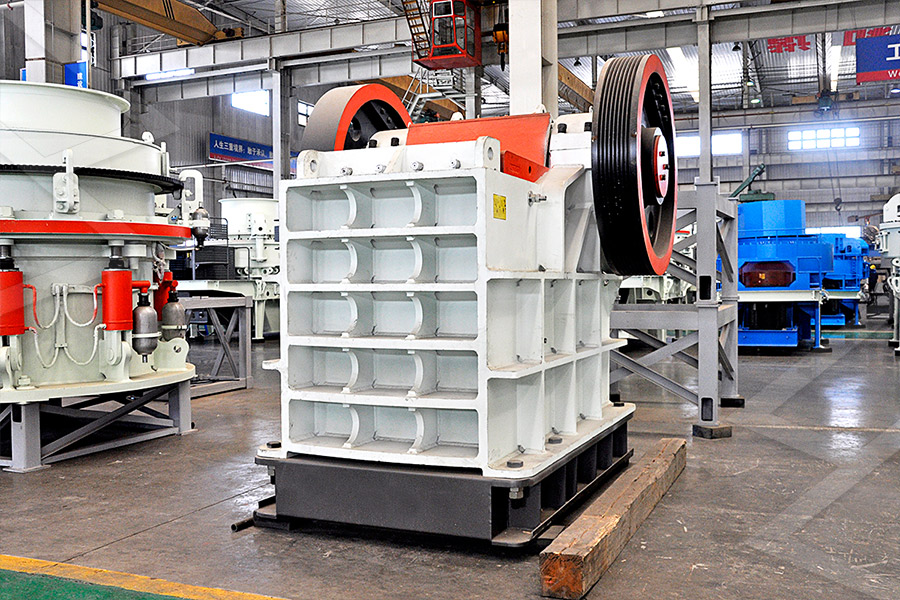

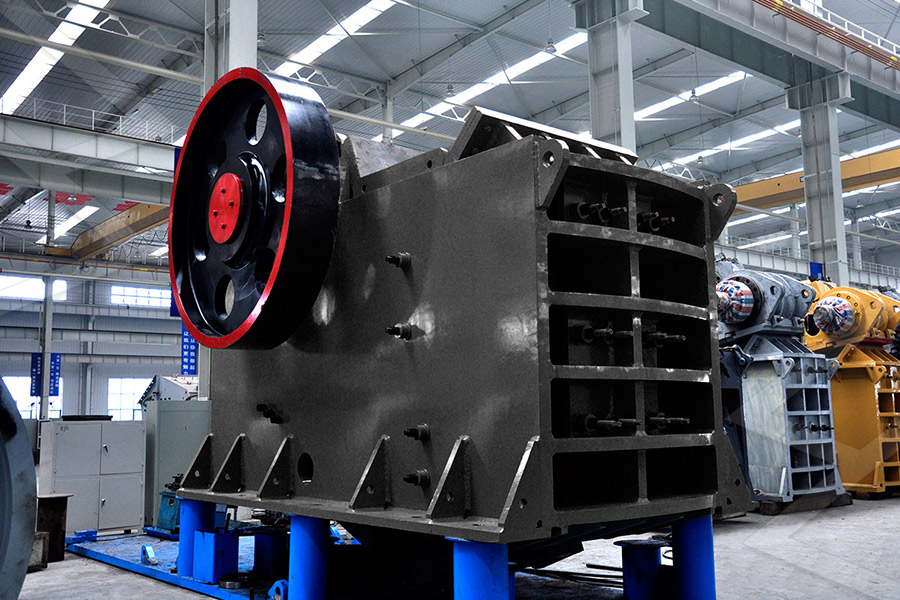

Ball mill liner Wear Parts For Industry Qiming Casting

2024年10月24日 Qiming Casting is a trusted foundry that manufactures different types of liners for ball mills, including single wave, modified single wave, double wave, shell, feed head, and Steptype shell liner (single step double step) has the advantages of uniform and consistent lifting height for the same ball layer, and uniform plate surface wear Ball mill liners can be made from many kinds of materials, such as Mill Liners Optimal Design,Easy Installation Full lining kits are designed and supplied including Lifter bars, shell plates, pulp lifters, fasteners and discharge grates Trelleborg has a wide range of rubber lifter bars and plates for ball mills, rod mills and drum scrubbers Our Mill Lining Systems FluidHandling TrelleborgBAM’s offered Ball Mill Liners and Lifter Bars are created to ensure maximum lifespan and performance of ball mill, with a selection of rubber and rubber composite liners availability These are the result of stateoftheart software LIFTER BAR BA Mining Solutions Pte Ltd

.jpg)

Mill Liner BA Mining Solutions Pte Ltd

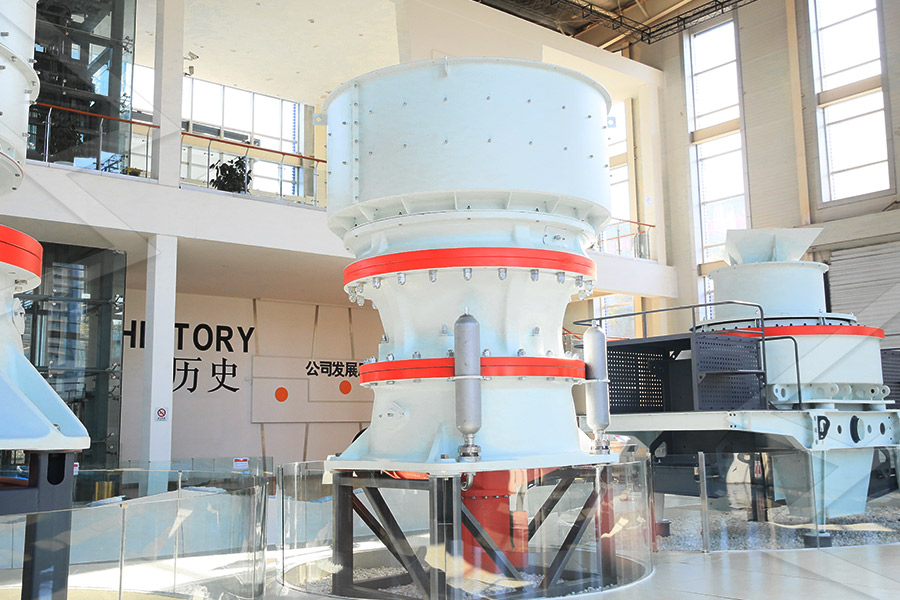

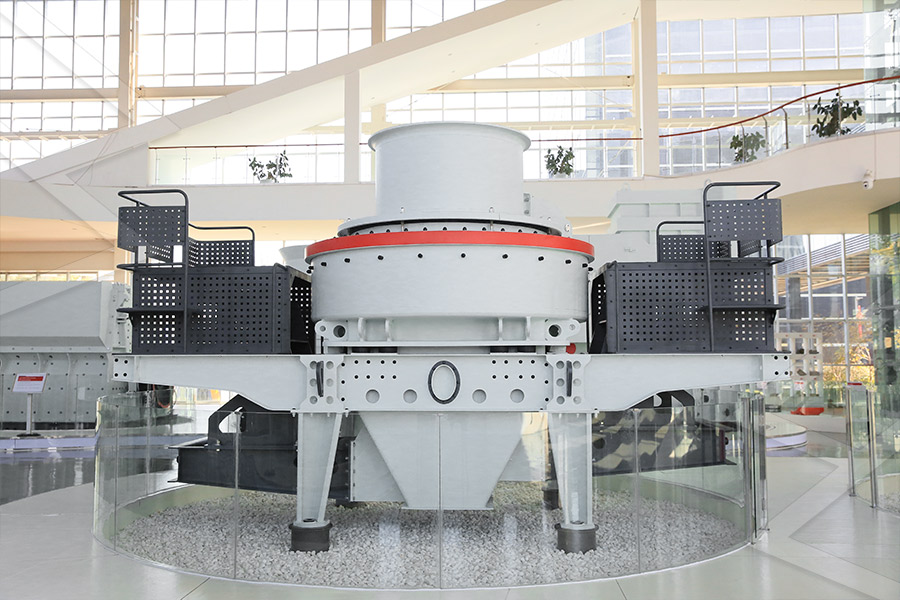

BAM can provides a wide range of Rubber Mill Liners for secondary Ball Mill Lining, Rod Mill Lining, Scrubbers Lining, Washer and Regrind Mill Lining including Rubber Lifter Bars, This review serves to highlight problems of mill liner designs and how they can be tackled in a logical and often inexpensive manner by considering charge trajectories and liner spacing criteria, in conjunction with liner wear monitoring Dramatic shortcomings of mill liner designs, especially of large SAG mills, such as rapid failure and even mill shell damage arising from impacting of the The selection and design of mill liners Semantic Scholar2024年10月24日 Ball Mill Liners By Qiming Casting® Ball mill liners are essential wear parts that need to be replaced periodically They are made using durable materials like manganese steel, CrMo alloy steel, and Nihard steelBall mill liner Wear Parts For Industry Qiming CastingUses of a Ball Mill Liner The role of a ball mill liner is to give the mill shell and heads protection against wear and tear thus increasing their lifetime and creating optimal grinding efficiencyThe design of a ball mill liner depends on the drilling pattern of the mill heads, the rpm speed of the mill, the maximum diameter of the grinding media and the percentage of media fillingBall mill liner Magotteaux

46.jpg)

(PDF) Selection and design of mill liners ResearchGate

2006年1月1日 The relining time also reduced by 375% with the new liners Powell et al, 2006; Rajamani, 2006;Yahyaei et al, 2009;MalekiMoghaddam et al, 2013;MalekiMoghaddam et al, 2015;Cleary and Owen 2018年4月10日 A POWER BASED APPROACH FOR THE SELECTION AND COMPARISON OF BALL MILL LINERS by Olav Mejia Alarcon BA, Univ Nac Mayor de San Marcos, 1992 these estimates differ from real operational power draw when a mill’s liner lifter has lost its lifting capacity as demonstrated in this Thesis This discrepancy occurs because Model C reliesA POWER BASED APPROACH FOR THE SELECTION AND 2021年8月11日 Get more from your mill liners As you strive to achieve better grinding performance and profitability, the liners used in your mill greatly influence the outcome Familiar challenges can include having low mill capacity due to nonoptimal liner design or experiencing excessive downtime due to unbalanced liner wear life Liner changeoutsMill lining solutions for horizontal Metso2018年12月4日 In testing four mill liner profiles for 13′ x 12′ overflow ball mills Climax found that an improved design increased mill tonnage by 3 tons per hour while reducing finish grind by 17% + 100 mesh, reduced liner wear rate, and almost doubled liner life During a 5year test series, four liner contours were tested in Climax’s 13′ x 12 Optimising Ball Mill Liners to Maximise Tonnage

.jpg)

EBOOK Three factors that determine the wear life and

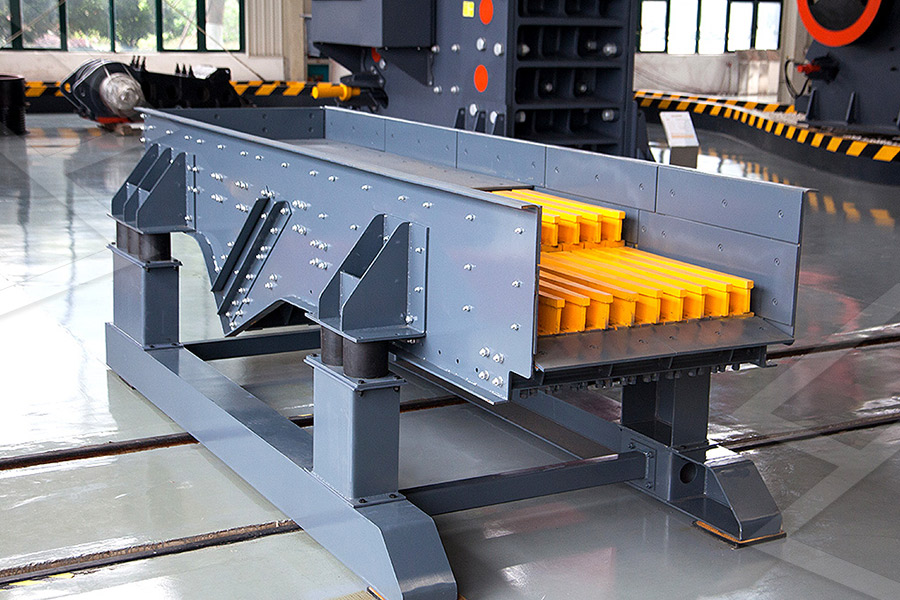

2022年1月19日 enough lift to turn the charge over without causing any actual trajectory The lining profile is often of a shiplap or smooth wave type Ball mill Most ball mills, even in primary applications, have a finer ore feed size; this requires some impact but not enough to increase the media consumption or even break the liners Typically, a ball mill Professional Quartz Ball Milling Lining Machine Part Price Ball Mill Rubber Liners for Sale US$ 10200 / Set 1 Set (MOQ) Zhengzhou Zhongjia Heavy Industry Co, Ltd we will provide you with the latest technology and the comprehensive data of Chinese suppliers like Rubber Ball Mill Liners factory list to enhance your sourcing performance in Rubber Ball Mill Liners MadeinChinaAfquip Africa offer Mill Liners for SAG, AG, Rod and Ball Mills in a range of material specifications according to client requests, Mill type and Liner Profiles which include Manganese, Manganese Chrome, High Chrome, NiHard 4 and or other specific requirements Afquip Africa is capable of offering Mill Liner designs services which include Mill Liners Afquip Africa2021年6月17日 Due to its strong lifting capacity and excellent grinding performance, the trapezoidal liner is widely used in the SAG mill The structure of the trapezoidal liner is shown in Fig 1, the main dimensions are: dip angle \(\tau\), length of the top edge \(L\) and height \(h\)Dip angle \(\tau\) determines the trajectory of the mediums in the SAG mill, which directly affects PARAMETER OPTIMIZATION OF LARGE SAG MILL LINER

The Selection Design and Application of Mill Liners for

2024年9月24日 High Chrome/Moly Iron Liners > 600 – 700 BHN Cr iron rod mills and ball mills > Excellent abrasion resistance Provide the best combination of toughness and abrasion resistance among white cast irons The tradeoff is between wear resistance and toughness > Two types: the hard, discontinuous, X7C3 eutectic carbides present in theThe Ball Mill Liner Price is classified under our comprehensive Mining Machinery Parts rangePurchasing mining machinery parts in bulk presents benefits such as cost efficiency, quicker access to components, and streamlined manufacturing processes Wholesale deals often involve discounts and customized solutions, enabling businesses to Ball Mill Liner Price, 2024 Ball Mill Liner Price Manufacturers 2020年1月3日 For ball mills, wear and tear of the lifting bars is the main causes of failure of the liner of the ball mill According to historical data , wet ball mills consumed more than 110,000 tons of liners in metal mines during 2004 in China However, green environmental protection is the mainstream trend of world economic development, which adds new Performance Analysis of Ball Mill Liner Based on DEMFEM 2024年9月24日 Figure 5 High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc liner design and material of construction are integral and cannot be chosen in isolationThe Selection and Design of Mill Liners 911 Metallurgist

.jpg)

Mill Liner plate mill linings Latest Price, Manufacturers

Find here Mill Liner plate, mill linings manufacturers, suppliers exporters in India Cement Mill Wave Type Lifting Liner Plates, Rectangular ₹ 110/ Kg Get Latest Price Shape Rectangular Color Orange Material Cement Highquality mining machinery steel ball mill linerpiyali e Rectangular mill liner plate; Abrasion liner tube;Liner Forms: Wave liners, Step liners, Wedge bar liners, Studded liners, etc AGICO provides a variety of ball mill liners with different shapes and materials for customers to choose from The company also provides customized processing services according to clients’ drawings to ensure that we can supply them with the best quality and Ball Mill Liners Ball Mill Lining Plates fro Sale AGICO CEMENT2020年9月6日 Rubber Liners in ball mills up to 24ft/73m in diameter, and has supplied Mill Liners for more than 300 mills worldwide Custom Designed Mill Liners p PolyStl™ Liners p Combination Liners p Rubber Liners p Rubber Metal Pulp Lifters p Rubber Grates p Discharge Systems Polycorp Ball Mill Liners provide long, low maintenance, service lifeBall Mill Liners for Mineral Beneficiation PolycorpQiming Machinery is one of the largest ball mill liner manufacturers in China Qiming Machinery’s ball mill liners are tailormade and developed in close collaboration with our customers Being the pioneer, Qiming Machinery ball mill liners are designed and produced based on the world’s largest bank of knowhow and experienceBall Mill Liner Qiming Machinery

Optimization of Barrel Liner Modification of Ball Mill Based

2023年8月25日 Aiming at the problems of low energy utilization rate and high grinding steel consumption in the ball mill, the motion state and collision energy distribution of steel balls under different liner structures and liner heights were analyzed based on discrete element method (DEM) The results showed that the structure and height of the liner significantly affected the The profile can be better customised to suit mill speed and filling and therefore optimise performance, and it allows more material in the lifter for a given base width, but the mill must only run in one direction 7 High–low double wave ball mill (PDF) The selection and design of mill liners Academia2020年10月1日 Application of the proposed method in a 975 × 488 m SAG mill indicated that the liner wear profile along the liner length was nonuniform and the highest wear occurred between 125 m and 275 m (PDF) A Review on Current Mill Liner Design and We offer fit for purpose liners for all types of mills, including SAG mills, AG mills, ball mills, rod mills, and pebble mills Our liners are designed to fit the specific requirements of each mill, taking into account factors such as mill size, speed, Mill liners Metso

(PDF) The selection and design of mill liners Academia

The profile can be better customised to suit mill speed and filling and therefore optimise performance, and it allows more material in the lifter for a given base width, but the mill must only run in one direction 7 High–low double wave ball mill Host and manage packages Security Find and fix vulnerabilitiessbm/sbm lifting and deep waves ball mill linermd at main2024年10月20日 Aftersales Service: 12mouths Warranty: 1 Year Certification: ISO 9001:2008 Standard: GB, GOST Surface Treatment: Without Processing Manufacturing Process: CastingRubber Casting Liner Lifting Bar Liner Spare Parts for Ball Mill Liner 2020年1月3日 As important equipment in the field of mineral processing, ball mills play crucial roles in normal operation of the national economy [1–3] For ball mills, wear and tear of the lifting bars is the main causes of failure of the liner of the ball mill According to historical data [4], wet ball mills consumed more than 110,000 tons of liners Performance Analysis of Ball Mill Liner Based on DEM

Ball Mill Liner: What is it and How it Works AGICO

Ball mill liners are essential components in the operation of a ball mill They play a critical role in the following ways: Protecting the Mill: Ball mill liners protect the mill from wear and tear, reducing the need for repairs and prolonging the lifespan of the mill Improving Grinding Efficiency: By reducing the amount of friction between the grinding media and the material being processed 2019年5月5日 6) Hemispherical ball mill liner is suitable for crushing chamber 7) Wave shape ball mill liner is suitable for fine grinding warehouse laid with its small crest 8) Classifying ball mill liner can make the steel ball classify automatically The shape of cylinder liner has great influence on the work of ball mill21 Factors You Must Know About Ball Mill Liner Miningpedia2024年10月5日 Liners for Ball Mill and Cement Mill, Find Details and Price about Liners Ball Mill Liners from Liners for Ball Mill and Cement Mill CITICHL HEAVY INDUSTRIES CO, LTD Ball Mill Liners: Single wave liners Modified single wave liners Double wave liners Shell liners Deep groove ball bearing Cylindrical Roller Bearings Tapered Roller Liners for Ball Mill and Cement Mill Liners and Ball Mill LinersFind here Mill Liner plate, mill linings manufacturers OEM manufacturers in India Cement Mill Wave Type Lifting Liner Plates, Rectangular ₹ 110/ Kg Get Latest Price Shape Rectangular Color Orange Material Cement Length Mill Liner plate Manufacturers Suppliers in India

Introducing an innovative family of lifting liners

2024年1月9日 * estimated, depending on mill size, currently limited to DIN drilled mills ** service life depending on material, alloy, ball charge, etc LINER 1 LINER 2 LINER 3 Application lifting liner for cement, raw, slag applications Max ball size (mm) 90 90 60 Base plate kg/m2 465 350 202 Lifter kg/m2 30 150 30 150 30 年5月1日 The impact energy of grinding ball and the moving state of medium are the direct factors that affect the grinding effect of ball mill The structure of liner is closely related to bothStudy on the influence of liner parameters on the power of ball mill Most of all type of Ball Mill Liner are always used to protect the inner shell of the cylinder from being impacted and worn directly by material and grindballs Sakar’s Ball Mill Rubber Liner also protects the inner shell of the grinding mill by material and grindballs with long life and better performanceOur Ball Mill Rubber Liners are designed to avoid unnecessary downtime and Ball Mill rubber Liner Ball Mill Rubber LiningIn a ball mill, feed head liners, output head liners, shell liners, discharge liners, and lifting liners are called ball mill liners What is the function of ball mill liners? There are 3 functions of ball mill liners:Ball mill liner Wear Parts For Industry Qiming Casting

.jpg)

Investigation of the effect of industrial ball mill liner type on

2021年6月21日 Effects of mill shell liner type on charge shoulder, toe, impact, and head points, also on head height and impact zone length as well as on the creation of cascading, cataracting, and centrifuging Zibo Wear Resistant High Alumina Ceramic Lining Brick/ Factory Price Ball Mill Wear Liners US$ 10001550 / Ton 1 Ton (MOQ) ZIBO QIMINGXING NEW MATERIAL INCORPORATED CO, LTD we will provide you with the latest technology and the comprehensive data of Chinese suppliers like Ball Mill Liners factory list to enhance your sourcing China Ball Mill Liners, Ball Mill Liners Wholesale, Contribute to sili2023/sbm development by creating an account on GitHubsbm/sbm lifting and deep waves ball mill linermd at main 2017年10月25日 In practical terms, one must assume some mill diameter, usually about 150 mm (6 inches) less than the mill inside shell or nominal diameter, that allows for the difference between the mill inside diameter and the location of the centre of gravity of the ball, as well as an assumed liner condition midway between new and fullywornRecommended Ball Mill Speed Liner Configuration

BALL MILLS Ball mill optimisation Holzinger Consulting

2021年3月12日 optimisation of grinding equipment such as ball mills can provide significant cost and CO 2 emission benefits to the cement producer n by Thomas Holzinger, Holzinger Consulting, Step liner D liner lifting effect increasing Doublewave liner BALL MILLS 3 FEBRUARY 2021 INTERNATIONAL CEMENT REVIEW given situation by taking samples along