Driving A Rock Crusher Equment Cost

.jpg)

Rock crusher production and operation cost analysis

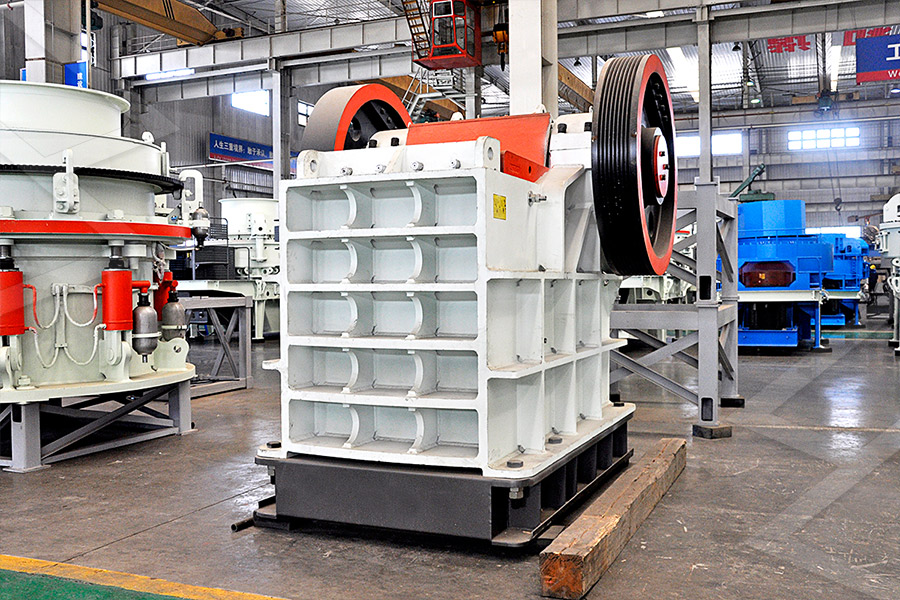

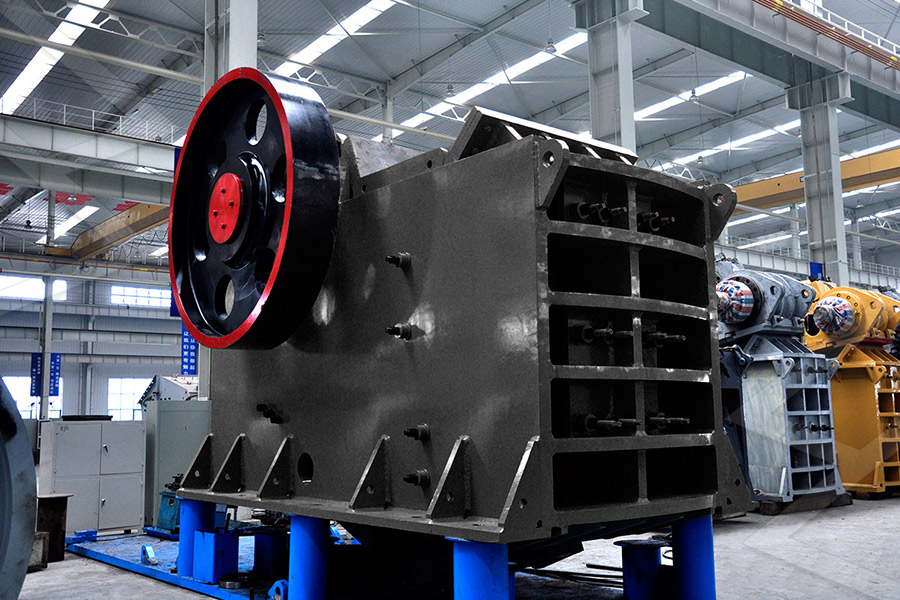

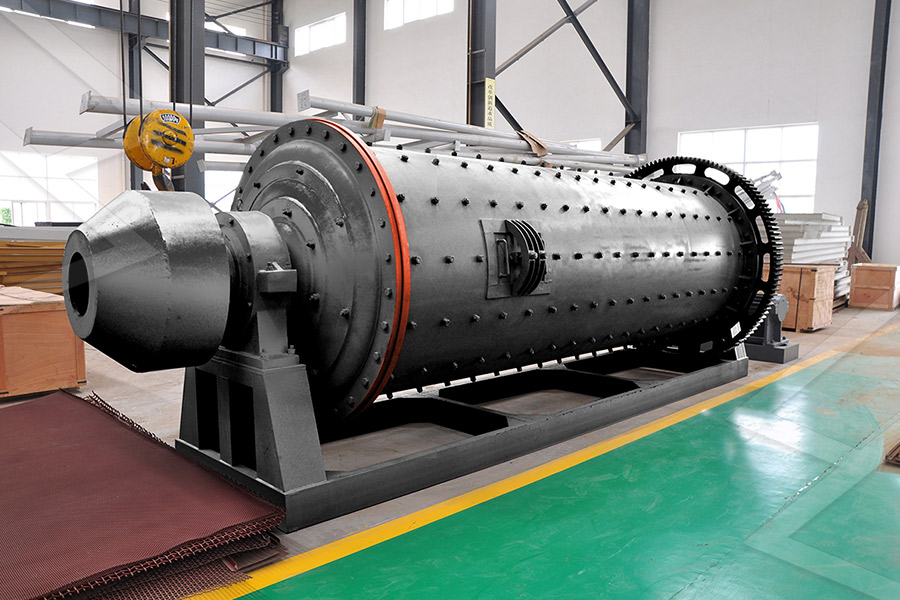

2024年10月13日 A rock crusher production and operation cost is the sum total of direct and indirect costs incurred in producing a rock crusher Direct costs include materials, labour, and overhead expenses while indirect costs include machine wear, depreciation, and transportation1 Acquisition Costs: The first step in calculating the owning costs of crushers is considering the initial acquisition cost This includes the purchase price of the equipment, transportation expenses, taxes, and any additional fees associated with acquiring the crushercalculation of owning and operating costs of crushers2023年12月8日 The owning costs for the crusher are: Owning costs = $100,000 + $20,000 + $10,000 = $130,000 The operating costs for the crusher are: Operating costs = ($005/kWh) * (100 tons/day) * (8 hours/day) * (1000 Calculation of owning and operating costs of a When evaluating crushing equipment suppliers, crusher manufacturers should quantify both costs: purchase price and operating costs Before you purchase, ask for reference customers to visit Selecting Equipment Why are there so many types of equipment?How Much Does It Cost To Operate a Crusher? Resource

Crusher Operating Costs: How to Optimize and Reduce

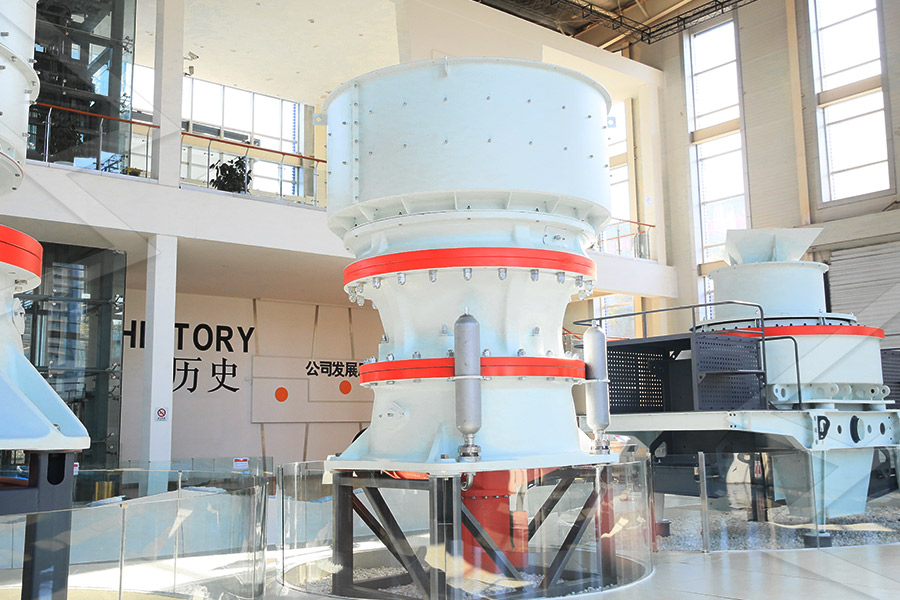

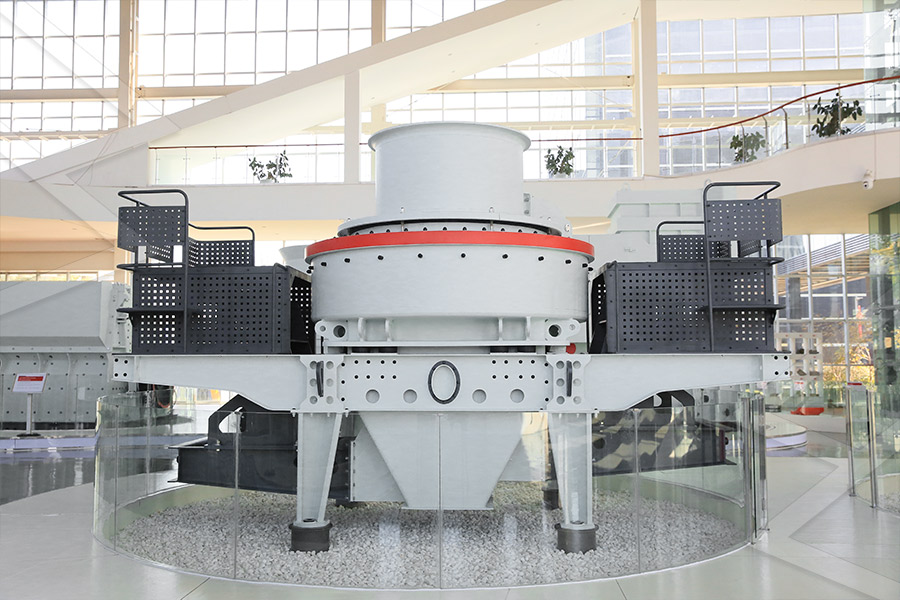

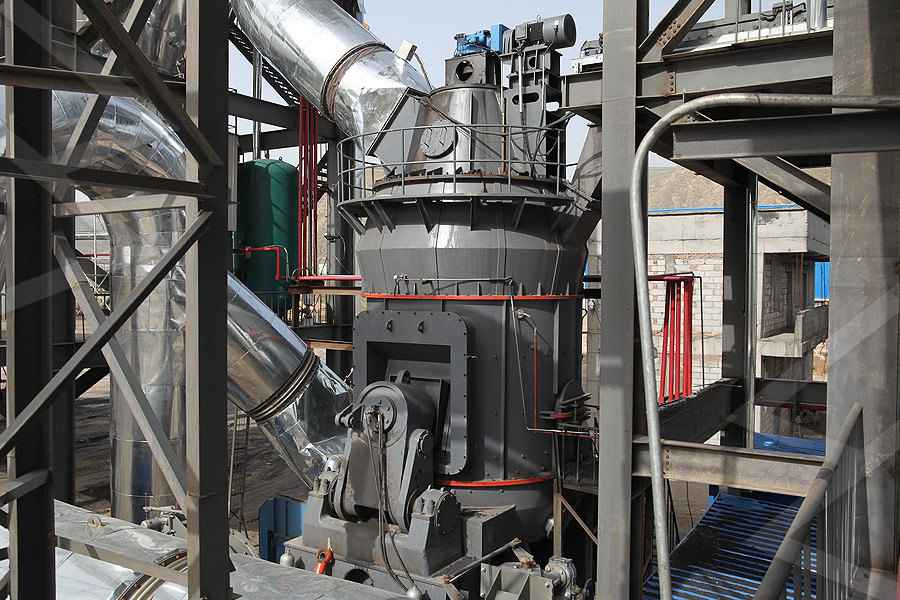

2016年1月11日 The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eighthour crushing day are easy to calculate The figures must be regarded only as a rough guide to the average costs of modern installations ; they are direct costs and include no overhead charges2024年7月17日 Understanding material characteristics and defining production needs can help you choose the right crushing method, saving costs throughout the production process Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushingTypes of Crushers: Choosing the Right One for Each Stage2024年10月14日 What machines are required for a stone crusher plant, and what is the function of each? Here, you'll discover 11 stone crushing equipment needed for stone crushing, from primary crushers to fine crushers and What Machines Do Stone Crushing Plants Need?By understanding the cost implications of each type, you can make an informed decision that maximizes efficiency while minimizing expenses So buckle up and join us on this journey as we uncover which rock crusher is not only powerful but also comparison rock crusher operating costs – stone cruxder

.jpg)

rock crushing equipment operational cost

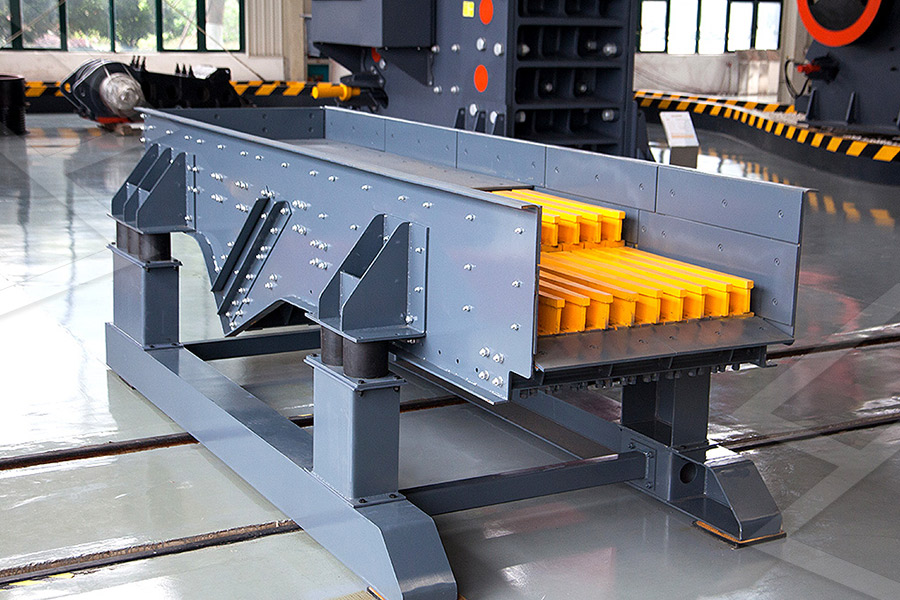

One of the primary factors that contribute to operational cost is energy consumption Rock crushing equipment requires significant amounts of energy to operate, and this energy consumption translates into increased operating costs The type of equipment used and the productivity of the crushing plants also contribute to energy consumption2023年10月12日 Explore the intricate realm of operating costs associated with crushing and screening equipment Discover insights on managing expenses related to energy consumption, maintenance, labor, and environmental compliance Gain knowledge on cost optimization for a sustainable and ethically responsible industrial landscapeUnderstanding the Operating Costs of Crushing and Screening Equipment2023年2月23日 Here are some frequently asked questions about portable rock crushers: What is the price range for a portable rock crusher? Prices for portable rock crushers can vary widely depending on the manufacturer, model, and features They can range from a few hundred dollars to several thousand dollars How long does it take to set up a portable rock Your Ultimate Guide to Buying a Portable Rock Crusher2024年10月22日 【Jaw Crusher Parts】Flywheel, pitman, hydraulic cylinder, toggle plate, eccentric shaft, fixed jaw, moving jaw, etc 【Jaw Crusher Working Principle】Motor drive belt and pulley, the eccentric shaft pushes the movable jaw against the fixed jaw, generates the crushing action, compresses the material to the desired sizeThe crushed materials are discharged from Jaw Crusher JXSC Machine

.jpg)

Rock Crusher Eastman Rock Crusher

Stone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industriesAt present, there are two types of stone crushing machines 2024年6月28日 Crusher Rock: Key Takeaways Crusher rock machines are designed to break down rocks into smaller, more manageable pieces Different types of crusher rock offer various features and benefits for use in different industries Consult experts when choosing a rock crusher Consider factors such as cost, mobility, purpose, size, and qualityCrusher Rock: Exploring the Types of Rock CrushersInvesting in a Compact Crusher is a big step for any contractor While investment costs are significant the reward is also massive and the machine pays for itself by saving on disposal, trucking, and new aggregate costs Compact crushers cost anywhere from $500,000 to How Much Does a Compact Crusher Cost? RUBBLE MASTER2023年12月8日 drivespreadsheet Total cost The total cost of setting up a stone crusher plant in India can range from ₹5 million to ₹20 million The specific cost will depend on a number of factors, including the size and capacity of the plant, the type of equipment used, the location of the plant, and the government regulations and environmental impact requirementsCost Sheet of Stone Crusher Plant in India CM Mining

Rock Crusher Conveyor Belt Efficiency Guide

2024年5月25日 Rock Crusher Conveyor Belt: Essential Components and Their Importance Understanding the Basics Definition and Functionality A rock crusher conveyor belt is an integral part of the rock crushing process It serves as a critical link between various equipment, including crushers, feeders, and screens, facilitating a continuous and automated production flow2023年12月8日 Material crusher are essential equipment in a variety of industries, including mining, construction, and recycling They are used to reduce the size of materials, making them easier to handle and transport The owning and operating costs of a material crusher can vary depending on a number of factors, including the type of crusher, the size of the crusher, and Calculation of owning and operating costs of a material crusherOperational Costs: Operational costs encompass the expenses incurred during the daytoday use of the crusher These costs mainly consist of fuel or electricity consumption, regular maintenance, spare parts, and consumables such as lubricants It is important to consider the type and capacity of the crusher, as well as the expected utilization calculation of owning and operating costs of crushersAbout Us Shibang Industry Technology Group Co, Ltd is one hightech enterprise, which involves RD, production, sales and service as well In the past 20 years, we devote to producing mining equipments, sand making machines and industrial grinding mills, offering expressway, rail way and water conservancy projects the solution of making high grade sand and matched Impact Crusher/Jaw Crusher / Cone Crusher Manufacturer, Rock Crusher

.jpg)

Rock Crushers Manufacturer JXSC

A rock crusher works by applying force to break large rocks into smaller, more manageable pieces Gold rock crushers are specifically designed to break down rocks to extract precious metals, while a hard rock crusher is built to handle From helping you select the perfect crusher to providing ongoing support and flexible financing options, we make the process of purchasing and operating a rock crusher as seamless as possible Our goal is to ensure you have the right equipment and support to maximize productivity and efficiency in your operationsRock Crusher Buying Guide: How to Choose the Best Crusher 2013年6月24日 Hi everyone, I thought i'd share my petrol driven rock crusher It's a 11hp Honda driving the crusher and the crusher chamber is about 250mm in diameter I got my ideas from the "Reeds rock crusher" that is found on the Home made rock crusher Prospecting AustraliaAn FAE stone crusher from the STCL series is just what you need, with the ability to work up to 6" deep Do you need to crush stones up to 12" in diameter and mill rock slabs using a 90180 hp tractor? FAE recommends the RSL series: thanks to its compact dimensions, it’s perfect for working in tight spaces up to 11" deepRock Crushers, for Tractors and Skid Steers For Sale FAE

.jpg)

Electric Rock Crusher Indoor, Underground Crushing

Electric Rock Crusher RUBBLE MASTER offers electric rock crushers that can hook up to the grid or to a generator Lower Operating Cost Fewer moving parts and less energy losses Easy to Maintain Impact Crushers Available with a selfcontained dieselelectric direct drive or fullyelectric drive Capacity Inlet opening Crusher unit Mining Rock Crusher 330725t/h Mining Rock Crusher 250300kW Cone Crushing Machine TONGHUI VSI Stone Crusher 910mm Impeller Mining Rock Crusher 50mm Feed Vertical Shaft Impact Crusher VSI Sand Making Machine 2200RPM Jaw Rock Crusher Flywheel Design Hydraulic Jaw Crushing Machine PE1200*1500 PE900*1200 CE 88T Jaw Rock Crusher 400 Quality Mining Rock Crusher Jaw Rock Crusher factory 2024年8月18日 Rock crusher machine operators should continuously educate themselves and take refresher courses Staying updated on safety protocols and new equipment technologies is crucial Learning the proper shutdown process is essential for safety Buying is costeffective for those needing rock crushing equipment frequently or longtermPortable Rock Crushers for OnSite Crushing Certified MTP 2024年6月26日 RenttoOwn Option: Some rental agreements offer the opportunity to apply rental costs toward eventual purchase Cons: Potential LongTerm Cost: Extended rental durations may exceed the cost of outright purchase Dependence on Availability: Rental equipment availability may be impacted by high demand, leading to unexpected downtimeRent or Own Rock Crushing Equipment: The Pros Cons of

How To Choose A Rock Crusher 6 Tips For Right One

2 天之前 Using a rock crusher mining involves several key steps to ensure efficient and safe operation Here’s a general guide on how to use a rock crusher: Read the Manual Before operating the rock crusher industrial, carefully read and understand the manufacturer’s manual It provides essential information on safety, setup, and operationrock crusher machine price Select 2024 high quality rock crusher machine price products in best price from certified Chinese Hammer Crusher Machine manufacturers, China Crusher suppliers, wholesalers and factory on MadeinChina Drive: Electric Crushing Style: Extruding 1 / 3 Favorites High Quality Rock Stone PE 400X600 Primary rock crusher machine price MadeinChina2024年10月31日 Model: VYKIN 8JC Configuration: Jaw crusher Power System: Direct drive Engine: 14HP gas engine Fuel Consumption: 026 – 052 gal/hr, 158 gal capacity Electrical Control: Yes, wireless remote standard Hydraulic VYKIN 8JC Mobile Mini Tracked Jaw Crusher2024年7月17日 A crusher, also known as a stone crusher, is a machine that uses mechanical action to break large rocks, ores, or other raw materials into gravel or rock powder Crushers are widely used in ore crushing, aggregate production, Types of Crushers: Choosing the Right One for Each Stage

.jpg)

Crusher Aggregate Equipment For Sale

2024年3月5日 Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader Find Crusher Aggregate Equipment from KINGLINK, METSO Call for price Apply for Financing Rock crusher for sale Philippines is the equipment used to crush rocks into pieces of different desired sizes The rock crushing equipment for sale is generally used for gravel, sand and other construction applicationsSome of the most common aggregate types in rock crushing are gravel, limestone, and gravelIn fact, the type of rock you plant to process will determine the type of Rock Crusher for Sale Philippines Breaking Rock Into Small 2024年10月24日 Valentini 'L' Series Rock and Stone Crushers for 70HP170HP Tractors, in 4ft to 75ft Widths Rock and Stone Crushers That Work For You!! Asphalt Grinders Milling Machines, Soil Stabilizers All GEAR Side Drive in Oil Bath Gear Box NO Belts, NO Chains Only Excellent Results Excellent Power Transfer! Valentini L1500 Recovering Valentini 'L' Series Rock Stone Crushers, Iowa Farm Costeffective: Renting a rock crusher is often more costeffective than purchasing one outright This is especially true if you only need the crusher for a short period of time Convenience: Renting a rock crusher is a convenient way to get the equipment you need without having to purchase it yourself You can often find rock crushers for rent Rock Crushers Mellott

.jpg)

Stone Crusher Rock Crushing Machine

2024年10月6日 Stone Crusher, also known as rock crusher, is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust It utilizes a highpressure force to crush the rocks and is widely used in various industries such as construction, mining, metallurgy, and recycling Customized crusher with reliable price We offer more than 5 天之前 An advanced rock crusher with dust suppression features can help you reduce this risk and keep your employees safe High initial investment: For most aspiring rock crushers, the cost of purchasing a new rock crusher is one of the biggest barriers to entry Look for a company like Senya Crushers that produces highefficiency equipment at Rock Crushing 101: A Beginner's Guide Senya Crushers2024年10月31日 The smallsized Senya 3 MICRO Jaw Crusher is our entry level crusher and can produce 200300 tons per day (realistically filling 1 dump truck per hour minimum) Our customer’s reported average ROI is 4 months with $225,000+ 1st year savings at ~15 truckloads per month For larger scale crushing (6080 tph), see the Senya 6 MICRO Jaw Crusher For Rock Crusher, Small Mobile Crusher VYKIN Crushers2020年6月3日 The company's cone crushers are ideally suited to process mediumhard to hard and abrasive natural rock When linked with primary crushers and screening plants, the MOBICONE delivers excellent cubic final grains in the secondary and tertiary crushing stages, according to the manufacturer While the initial cost of a cone crusher is quite A Detailed Overview of Cone Crushers and What You Need

HSI Or VSI Impact Rock Crusher: Which Is Best

2023年8月21日 Maintenance Operating Costs Our rock crusher experts have the realworld expertise necessary to advise you on the best solution for your operation to maximize productivity and profitability 100 Mellott Drive 2023年2月15日 Protodyakonov rock classification is based on Protodyakonov scale to classify the hard rock and soft rock f = 1520: Extremely strong rocks, such as very strong granite, limestone, quartzite, etc f = 810: Strong rocks, such as strong granite, strong sandstone, etc f = 46: Medium strength rocks, such as common sandstone, iron ore, etcWhich Crusher Is Suitable for Your Hard Rock? Fote How Much Does It Cost To Operate a Crusher? By Chris Nawalaniec Crushing equipment is the heart of an industrial materialprocessing system The size reduction choice you make will have a profound impact on the profitability of your business When the right choice is made, you should expect many years of profitable operation How do you make the right crusher choice? How Much Does It Cost To Operate a Crusher? Resource 2023年11月28日 Caliche rock cost Caliche rock costs $45 to $100 per ton and $30 to $80 per cubic yard A Caliche driveway costs $117 to $662 per square foot Caliche can mean higherquality limestone and calcite rock, like decorative Arizona gravel Crushed granite prices Decomposed or crushed granite costs $1 to $3 per square foot2024 Gravel Prices Crushed Stone Cost (Per Ton, Yard

.jpg)

Stone Crusher Machine Price: Factors, Range, and Ways to

2023年2月28日 The price of a stone crusher machine is one of the primary factors that customers consider before making a purchase Therefore, understanding the factors that affect the price of these machines, the price ranges of different types of machines, and ways to save money on them can be crucial for customers The rise in urbanization and 2018年8月7日 The design and construction of a prototype rock crushing machine was performed this is with a view to ensuring that the designed crusher is capable of crushing rocks, lime stone and solid minerals (PDF) Design and Construction of Rock Crushing Machine 3 天之前 This page is about the Rock Crusher added by Railcraft For other uses, see Rock Crusher The Rock Crusher is a multiblock structure added by Railcraft This machine is used to process various items and blocks This machine runs off of Redstone Flux (RF), using 16,000 RF/use, and takes up to 160 RF/t At full power, an operation takes 5005 seconds (as there is Rock Crusher (Railcraft) Official Feed The Beast WikiChina Rock Crusher wholesale Select 2024 high quality Rock Crusher products in best price from certified Chinese Crusher manufacturers, Crushing Equipment suppliers, wholesalers and factory on MadeinChina Drive: Elecrtric or Diesel Crushing Style: Extruding Milling 1 / 6 Favorites Portable China Rock Crusher, Rock Crusher Wholesale, Manufacturers, Price

VSI Crushers REMco

Feed rates are from 15 to 1500 TPH Machine drive powers range from 50hp to 1500hp and feed sizes can be from 4” (100 mm) to 1/8" (25 mm) or less rotors has lowered the wear parts operating cost of the RockMax to a level equal to or less than any fine head cone crusher This rate is for cost per net ton of finished product regardless of Silica content in your rock is a driver for material abrasivness Feed size describes the largest input piece dimension diameter Material hardness has a significant affect on crusher performance it doesn't exclude an impact crusher from processing hard rock The harder to rock gets the smaller the feed size needs to be to avoid damagesJaw and Cone Crusher Myths Total Operating Costs